Consult your bolt customization experts

To provide customers with products and services of quality safety supply chain security, and cost saving.

Contact Us Now

Unlike bolts, the biggest feature of threaded rods and double ends is that there is no head part, only the threaded rod part, Because of this feature, they usually require nuts on both sides of the thread.

Din 976 is fully threaded, while the stud rod is smooth in the middle and threaded on both sides. Since they're mostly used for links, they're usually rated 10.9/12.9/B7grade.

Standard

| Approximate weight in Kgs per metre per pc. | |||

| Size (MM) | Weight per Metre | Size (UNC) | Weight per Mtr |

| M2 | 0.0187 | ||

| M2.5 | 0.030 | ||

| M3 | 0.044 | ||

| M3.5 | 0.060 | ||

| M4 | 0.078 | ||

| M5 | 0.124 | ||

| M6 | 0.177 | ¼” | 0.194 |

| M8 | 0.319 | 5/16” | 0.323 |

| M10 | 0.500 | 3/8” | 0.469 |

| 7/16” | 0.650 | ||

| M12 | 0.725 | ½” | 0.896 |

| M14 | 0.970 | 9/16” | 1.096 |

| M16 | 1.330 | 5/8” | 1.342 |

| M18 | 1.650 | ||

| M20 | 2.080 | ¾” | 2.021 |

| M22 | 2.540 | 7/8” | 2.756 |

| M24 | 3.000 | 1” | 3.638 |

| M27 | 3.850 | 1 1/8” | 4.545 |

| M30 | 4.750 | 1 ¼” | 5.718 |

| M33 | 5.900 | 1 3/8” | 6.842 |

| M36 | 6.900 | 1 ½” | 8.281 |

| M39 | 8.200 | 1 5/8” | 9.726 |

| M42 | 9.400 | 1 ¾” | 11.231 |

| M45 | 11.000 | 1 7/8” | 13.038 |

| M48 | 12.400 | 2 | 14.741 |

fully threaded rod/din976/din975

FOB Price: US $0.5 - 9,999 / Piece

Supply Ability: 10000 ton per Month

Surface treatment: Plain, Zinc Plated(ZP), GALVANIZED, HDG, Hot dip galvanized, Dacromet

Material: Carbon Steel / Alloy Steel / Stainless Steel / Brass / Copper

Standard: DIN / GB / UNC / BSW /JIS etc.

Certificate: ISO9001 ISO14001 ISO45001 SGS

Grade: 4.8 8.8 10.9 12.9 A2-70 A4-70 A4-80 etc.

What are they used for

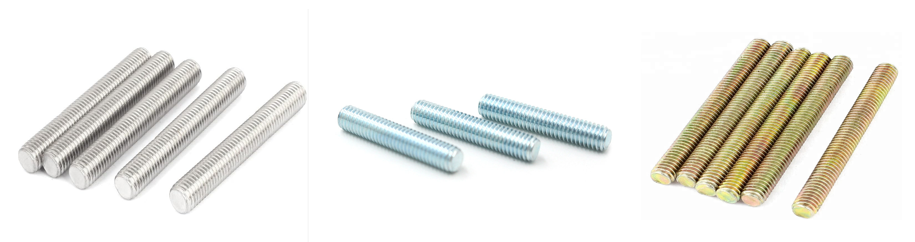

304 Stainless Steel Thread Rod M6,8,10,12 Bright Zinc-Plated Thread Rod Thread Rod Yellow Zinc Plated Din975

Din976 Thread rod is widely used in petroleum, chemical industry, construction, bridge, textile printing and dyeing, mechanical hardware, medical, decoration, shipbuilding and other light and heavy industries.

Our experience in producing threaded bolts for over 10 years gives us the confidence to solve more fastening problems. Different from bolt products, the length of threaded rods is longer, ranging from 1m, 2m, 3m and even longer. This poses a great difficulty in processing as experienced engineers are required to precisely control temperature during modulation, otherwise, the tensile strength and hardness cannot meet the standard.

In addition, there may be problems of blunt teeth during threading, which may cause nuts to loosen. This enables us to produce goods that fully comply with customer standards, including all thread rod strength grade 8, 10, and even higher strength level.

Manufacturing Process

The production process of threaded rods involves several key steps to ensure the manufacturing of high-quality products. Here is a brief overview of the production process for various types of threaded rods, including All Thread Rods, Acme Thread Rods, and Metric Thread Rods, along with specific sizes such as 3/8", 5/8", M10, M6, and M8. Additionally, we will touch upon the galvanization process and the role of a reliable all thread rod supplier.

1. Raw Material Selection:

The production process begins with the careful selection of high-quality raw materials, typically steel, to meet the required specifications for the desired threaded rod type. The material should possess suitable mechanical properties and durability.

2. Rod Cutting:

The selected steel rods are cut into appropriate lengths according to the specific requirements of the threaded rod size, such as 3/8", 5/8", M10, M6, or M8. Precision cutting ensures accurate dimensions and facilitates the subsequent manufacturing steps.

3. Threading:

In this stage, the cut rods are passed through a threading machine. For All Thread Rods, Acme Thread Rods, and Metric Thread Rods, different threading dies or tools are used to create the specific thread pattern and size required. Threading can be done using various methods, such as rolling or cutting, to achieve precise and uniform threads along the entire length of the rod.

4. Galvanization (if applicable):

If galvanized all thread rods are desired, an additional step of galvanization is performed. Galvanization involves coating the threaded rods with a layer of zinc to provide corrosion resistance, making them suitable for use in outdoor or corrosive environments. The galvanization process helps to extend the lifespan of the threaded rods.

In summary, the production process of threaded rods involves raw material selection, rod cutting, threading, optional galvanization, quality control, and packaging. By following these steps, manufacturers can produce a wide range of threaded rods, including All Thread Rods, Acme Thread Rods, and Metric Thread Rods, in various sizes such as 3/8", 5/8", M10, M6, and M8. Partnering with a reliable all thread rod supplier ensures access to quality products that meet specific requirements.

Consult your bolt customization experts

To provide customers with products and services of quality safety supply chain security, and cost saving.

Contact Us Now