Consult your bolt customization experts

To provide customers with products and services of quality safety supply chain security, and cost saving.

Contact Us Now

CSK head self drilling screw is a type of fastener that is designed to drill its own pilot hole and thread into metal, without the need for pre-drilling. This type of screw is commonly referred to as a self-drilling countersunk metal screw or a stainless steel countersunk self-drilling screw.

As a manufacturer and expert in the field of countersunk self-drilling screws for steel, we understand the unique needs and requirements of our customers. Our products are engineered to provide exceptional performance, durability, and reliability in even the most challenging environments. With our extensive experience and expertise in this area, we are committed to delivering the highest quality products and services to our customers.

Standard

Brand Name: Yunteng

Finish: Plain

Material: Steel

Package: Small Box Packed

Certificate: ISO9001 ISO14001 ISO45001 SGS

FOB Price: US $0.5 - 9,999 / Piece

Supply Ability: 10000 ton per Month

Surface treatment: Plain, Zinc Plated(ZP), GALVANIZED, HDG, Hot dip galvanized, Dacromet

Material: Carbon Steel / Alloy Steel / Stainless Steel / Brass / Copper

Standard: DIN / GB / UNC / BSW /JIS etc.

Certificate: ISO9001 ISO14001 ISO45001 SGS

Grade: 4.8 8.8 10.9 12.9 A2-70 A4-70 A4-80 etc.

What are they used for

stainless steel CSK head self drilling screw 10-16 x 1"Black CSK head self drilling screw Zinc CSK head self drilling screw

It is used to connect the wood board and iron plate, and between steel sheets. It can be directly drilled into the hole by electric tools without tapping.

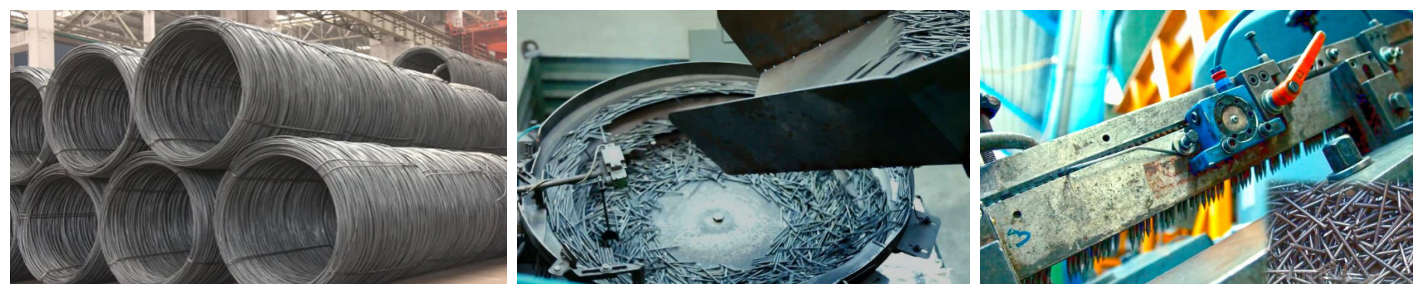

Manufacturing Process

The production process of a self-drilling screw involves several stages. First, the raw materials - usually steel or stainless steel - are received and inspected for quality assurance. The materials are then cut to the required length and shape using specialized machinery.

Next, the screws are heat-treated to improve their strength and hardness. This process involves exposing the screws to high temperatures for a specific duration before cooling them down. The screws are then tested for their mechanical properties, such as their tensile strength and torsional strength.

The screws are then coated with various types of protective coatings, such as galvanized or zinc coatings, to prevent corrosion and rust. This is done using electroplating, hot-dip galvanizing or other coating methods. The screws are then passed to the assembly line where they are packaged and labeled according to customer specifications.

Finally, the self-drilling screws are subjected to quality control checks, which include inspection for defects, dimensions, and strength. This ensures that the final product meets the quality standards required by the customer before being shipped.

Consult your bolt customization experts

To provide customers with products and services of quality safety supply chain security, and cost saving.

Contact Us Now